Timeline 2006

After the distillery was finally able to start production in December 2005, new major challenges for the operation of the distillery await at the beginning of 2006:

- On February 12, a fire breaks out in the kiln and destroys it to a large extent. The malt drying on the floor of the directly fired kiln had caught fire. The fire was prevented from spreading to other buildings by the quick and professional intervention of the Islay Fire Brigade. As it is not possible to malt and kiln for several months, the malt demand will be covered exclusively with barley malted according to Ardbeg specifications from the Port Ellen Maltings until the end of 2007. Subsequently, the company finally abandons the idea of producing all malt itself and later launches two different product lines: the normal Kilchoman produced with malt according to Ardbeg specifications (50 ppm) and the “100% Islay” made from self-malted barley (approx. 20 ppm), in which really all work steps from barley cultivation to bottling are carried out at Kilchoman itself – which thus corresponds to the postulated credo of a farm distillery.

- After the first casks were filled in December 2005, it took until the beginning of March 2006 until production can be resumed. Before that, numerous technical teething troubles had to be overcome. Here it took revenge that, for reasons of cost, the installation and connection of the stills and other equipment was not carried out by the manufacturer Forsyths but by a local company, a decision that Anthony Wills often regretted later. In addition, the boiler, which had been bought second-hand, was constantly causing problems.

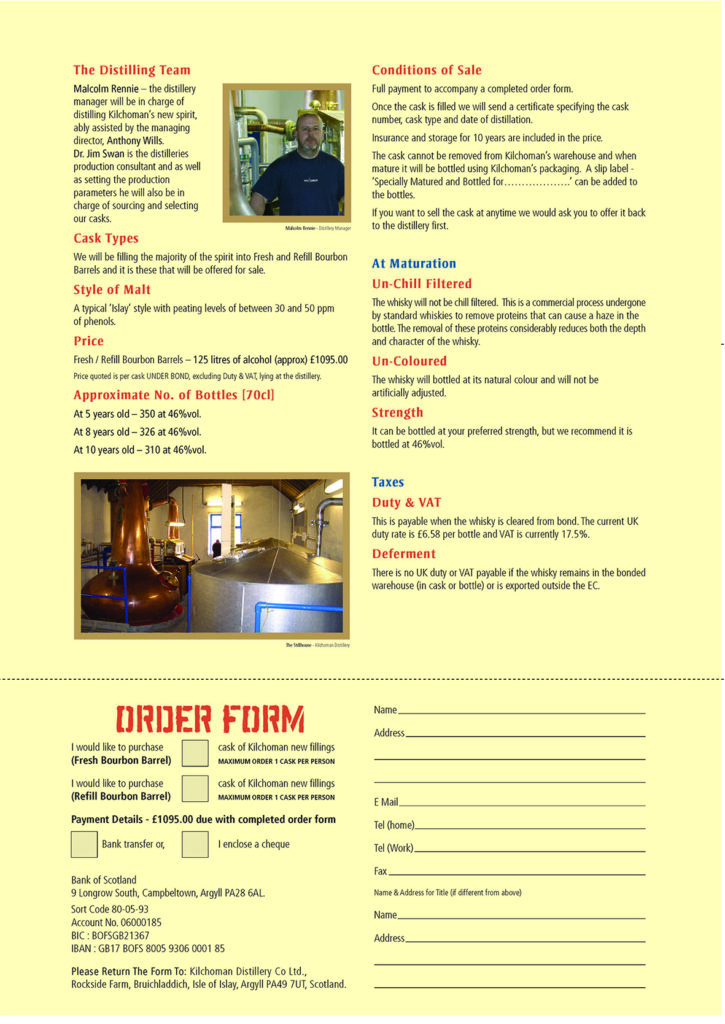

- In order to obtain urgently needed money for the ongoing operation of the distillery, a private cask programme was launched in 2005. Here, private individuals are given the opportunity to purchase a cask of Kilchoman New Make. Due to the delay in the start of production, the first private casks sold in 2005 were not bottled until March 2006. In addition, the delayed start of production in 2006 means that new purchasers are temporarily placed on a waiting list. The programme will end in mid-2007. Approximately 300 private casks were sold from 2005 to 2007.

Standard 1st and refill bourbon barrels were offered at a price of £1095. On request, it was even possible to purchase Oloroso sherry casks or casks filled with distillate from the farm’s own malted barley (later referred to as 100% Islay). However, the latter were only filled after the Kiln was put back into operation at the beginning of 2008.

- Kilchoman Open Day at the Islay Festival Fèis Ìle is 2 June. The programme was as follows:

- Guided tours every half hour from 11am to 4.30pm. Cost £2.00 per head

- 2.30pm: Tutored tasting of the different styles of Kilchoman New Spirit with the well known whisky and food writer Martine Nouet.

- Blind tasting of various Islay single malts. The winner will win one of the first bottles of Kilchoman Single Malt (here advised for 2010/11). £3.00 to enter

- BBQ and Seafood Bar throughout the day. The café is open and serves tea, coffee, homemade soups, paninis, baguettes, cakes and scones and most importantly refreshments such as beer, wine and soft drinks.

- During the whisky festival Kilchoman filled the 100th cask – a real landmark for the distillery.

- October 2006: Under the name Kilchoman Distillery Experience, the distillery offers whisky enthusiasts who want to gain a particularly deep insight into whisky production at Kilchoman the opportunity to work in one of the few distilleries in Scotland that handles the entire process from growing the barley on the farm to bottling the malt whisky after maturation.

During the stay, one shadows distillery manager Malcolm Rennie and gain hands-on experience in all aspects of malt whisky production – from barley to bottling.

The courses last 5 days from Monday to Friday. At the end of the week participants receive a certificate of attendance and a miniature bottle of the new spirit.

The maximum number of participants per course is 2. The cost is £500 per person.

- October 2006: Gavin Douglas is hired as mashman / stillman. Gavin previously worked as a mashman at Bowmore Distillery for two years. Together with Malcolm Rennie he forms the now two-person (!) production team.

- October 2006: Visitor Centre Manager Paula Lawson leaves Kilchoman. Kathy Wills, wife of Anthony Wills, initially takes over her duties, including running the café and shop.

.

- At the end of the year, the distillery reports an annual production of 50,000 litres of alcohol. 326 bourbon barrels, 23 Fresh Oloroso Sherry Butts and 4 Fresh Oloroso Sherry Hogsheads were filled. Even if an error has obviously crept in here: the Kilchomania database lists 373 and not 353 casks for 2006, this figure vividly shows the still modest scope of production compared with later years.

.

.